Introduction to Discus Cages

Discus cages are an essential piece of equipment for track and field athletes, coaches, and event organizers. They provide a safe environment for discus throwers to practice and compete, while also protecting spectators and other athletes from stray throws. Discus cages are designed to contain the discus within a designated area, reducing the risk of injury or damage to surrounding people and property.

In this comprehensive guide, we will explore the various aspects of discus cages, including their components, materials, regulations, and maintenance. Whether you are a seasoned track and field athlete or a newcomer to the sport, understanding the importance and proper use of discus cages is crucial for ensuring a safe and enjoyable experience.

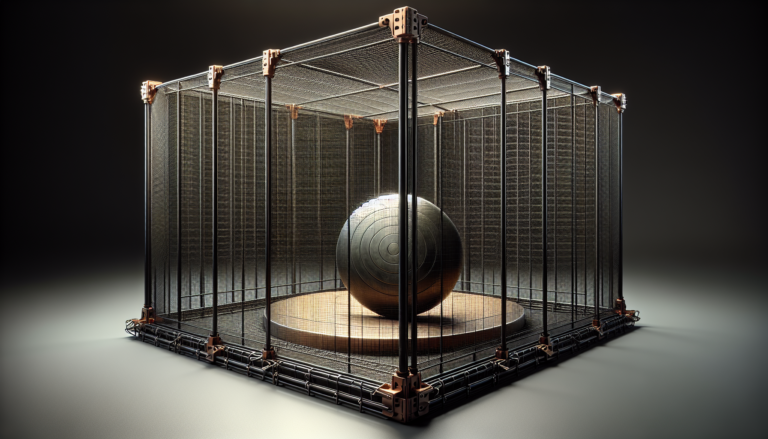

What is a Discus Cage?

A discus cage is a protective enclosure that surrounds the discus throwing area on a track and field facility. It consists of a sturdy frame, typically made of powder-coated aluminum, and a high-quality netting system that catches stray discus throws. The primary purpose of a discus cage is to enhance the safety of athletes, officials, and spectators during discus throwing events.

Discus cages come in various sizes and configurations to accommodate different levels of competition and training. They are designed to meet the specific regulations set forth by governing bodies such as the International Association of Athletics Federations (IAAF), the National Collegiate Athletic Association (NCAA), and the National Federation of State High School Associations (NFHS).

Importance of Discus Cages in Track and Field

Discus throwing is a powerful and dynamic event that requires a high level of strength, technique, and precision. However, the nature of the event also poses potential risks, as the discus can travel at high speeds and in unpredictable directions. This is where discus cages play a crucial role in ensuring the safety of everyone involved.

By containing errant throws within a designated area, discus cages minimize the chances of the discus striking someone or causing damage to nearby structures. They also provide a sense of security for athletes, allowing them to focus on their technique and performance without worrying about the potential consequences of a misdirected throw.

Moreover, discus cages are essential for complying with safety regulations and guidelines set by various track and field organizations. Event organizers and facility managers must ensure that their discus cages meet the required standards to host official competitions and provide a safe environment for athletes to train and compete.

Components and Materials of Discus Cages

To ensure the highest level of safety and durability, discus cages are constructed using high-quality materials and components. Understanding the key elements that make up a discus cage can help you make informed decisions when purchasing, installing, or maintaining this essential piece of track and field equipment.

Main Components of a Discus Cage

A typical discus cage consists of several main components, each serving a specific purpose in ensuring the safety and functionality of the structure:

- Aluminum Uprights: The vertical posts that support the netting system and provide the structural integrity of the cage. These uprights are usually made of powder-coated aluminum for durability and weather resistance.

- Nylon Netting: The high-strength netting that encircles the throwing area and catches stray discus throws. The netting is typically made of durable, UV-resistant nylon material to withstand the impact of the discus and the elements.

- Hinged Net Stabilizer Extension Arms: Adjustable arms that extend from the uprights to keep the netting taut and stable. These arms also allow for easy access to the throwing area for maintenance and retrieval of the discus.

- Throwing Circle: The designated area within the cage where the athlete stands to perform their discus throw. The throwing circle is usually made of concrete or a similar durable material and has a specific diameter as per the regulations.

Material Specifications

To ensure the highest quality and longevity, discus cages are constructed using materials that meet strict specifications:

- Powder-coated Aluminum: The uprights and other structural components of the cage are made of aluminum that has been treated with a powder coating. This process enhances the corrosion resistance, durability, and aesthetic appeal of the aluminum.

- Nylon Netting: The netting material used in discus cages is a high-density, UV-stabilized nylon that offers excellent strength and durability. The netting is designed to withstand the impact of the discus and resist degradation from exposure to sunlight and other environmental factors.

By utilizing these high-quality materials and components, discus cages provide a reliable and long-lasting solution for ensuring safety in discus throwing events.

Regulations and Standards

To ensure a level playing field and the safety of all participants, discus cages must adhere to specific regulations and standards set by various governing bodies in the world of track and field. These organizations, such as the IAAF, NCAA, and NFHS, have established guidelines for the construction, dimensions, and performance of discus cages.

IAAF Regulations

The International Association of Athletics Federations (IAAF) is the global governing body for the sport of athletics, including track and field events. The IAAF sets the standards for discus cages used in international competitions, such as the Olympic Games and World Championships. Some key IAAF regulations for discus cages include:

- Minimum height of the netting: 4 meters

- Minimum width of the cage opening: 6 meters

- Specific angles for the netting panels to ensure optimal safety

NCAA Regulations

The National Collegiate Athletic Association (NCAA) governs college athletics in the United States, including track and field events. NCAA regulations for discus cages are similar to those set by the IAAF, with a few minor differences to accommodate the specific needs of collegiate competitions. Some notable NCAA regulations include:

- Minimum height of the netting: 4 meters

- Minimum width of the cage opening: 6 meters

- Required markings on the throwing circle and cage panels

NFHS Regulations

The National Federation of State High School Associations (NFHS) sets the rules and standards for high school athletics in the United States, including track and field events. NFHS regulations for discus cages are designed to prioritize the safety of student-athletes while considering the resources available to high school programs. Some key NFHS regulations include:

- Minimum height of the netting: 3.66 meters (12 feet)

- Minimum width of the cage opening: 5.49 meters (18 feet)

- Specific requirements for the construction and installation of the cage

By adhering to these regulations and standards, manufacturers, event organizers, and facility managers can ensure that their discus cages provide a safe and fair environment for athletes at all levels of competition.

Optional Features and Accessories

While the basic components of a discus cage are essential for ensuring safety and functionality, there are several optional features and accessories that can enhance the performance and versatility of the equipment. These additions can help athletes, coaches, and event organizers customize their discus cages to meet specific needs and preferences.

Backup Net Systems

A backup net system is an additional layer of netting that can be installed behind the primary discus cage. This secondary net provides an extra level of safety by catching any discus throws that may penetrate or ricochet off the main netting. Backup net systems are particularly useful in high-traffic areas or where there are concerns about the proximity of spectators or other structures.

Some key benefits of backup net systems include:

- Enhanced safety for athletes, officials, and spectators

- Reduced risk of property damage from stray discus throws

- Increased peace of mind for event organizers and facility managers

Throwing Cages and Circles

In addition to the primary discus cage, some manufacturers offer specialized throwing cages and circles for other track and field events, such as shot put and hammer throw. These cages and circles are designed to meet the specific regulations and safety requirements of each event.

Throwing cages for shot put and hammer throw typically feature a similar construction to discus cages, with sturdy aluminum uprights and high-strength nylon netting. However, the dimensions and configurations of these cages may differ to accommodate the unique characteristics of each event.

Throwing circles, on the other hand, are the designated areas within the cages where athletes stand to perform their throws. These circles are usually made of concrete or a similar durable material and have specific diameters and markings as per the regulations of each event.

By investing in specialized throwing cages and circles, track and field programs can provide a safer and more efficient training and competition environment for their athletes across multiple disciplines.

Training and Maintenance

To ensure the longevity and optimal performance of discus cages, proper training and maintenance practices are essential. By educating athletes, coaches, and facility staff on the correct use and care of the equipment, track and field programs can maximize the benefits of their investment and minimize the risk of accidents or damage.

Training Resources

Providing comprehensive training resources is crucial for ensuring that athletes and coaches understand the proper techniques and safety guidelines for using discus cages. These resources can include instructional videos, written manuals, and hands-on workshops covering topics such as:

- Proper throwing techniques and form

- Safe entry and exit procedures for the throwing circle

- Correct positioning and alignment within the cage

- Identifying and reporting any equipment damage or malfunctions

In addition to event-specific training, it is also important to educate athletes on general safety practices, such as:

- Speed training: Developing proper acceleration and deceleration techniques to minimize the risk of injury

- Conditioning: Building strength, flexibility, and endurance to withstand the physical demands of the event

- Coaching: Seeking guidance from experienced coaches who can provide personalized feedback and support

By prioritizing comprehensive training and education, track and field programs can foster a culture of safety and responsibility among their athletes and staff.

Track Maintenance

Regular maintenance of discus cages and the surrounding track and field facilities is essential for ensuring the safety and performance of the equipment. A well-maintained discus cage not only provides a safer environment for athletes but also extends the lifespan of the equipment, saving programs money in the long run.

Some key maintenance tasks for discus cages include:

- Inspecting the netting and uprights for signs of wear, damage, or loosening

- Tightening any bolts or fasteners that may have come loose over time

- Cleaning the netting and uprights to remove dirt, debris, and rust

- Repairing or replacing any damaged components, such as torn netting or bent uprights

- Ensuring the throwing circle is level, clean, and free of cracks or chips

In addition to maintaining the discus cage itself, it is also important to regularly inspect and maintain the surrounding track and field facilities. This includes tasks such as:

- Checking the track surface for cracks, holes, or other hazards

- Ensuring proper drainage to prevent water pooling and slippery conditions

- Maintaining the grass or artificial turf in the field events areas

- Inspecting and repairing any damaged fencing, benches, or other structures

By implementing a comprehensive maintenance plan and training staff to identify and address potential issues, track and field programs can ensure that their discus cages and other equipment remain safe and functional for years to come.

Customer Support and Purchasing

When investing in a discus cage or other track and field equipment, it is essential to partner with a reputable manufacturer or supplier that offers comprehensive customer support and a user-friendly purchasing process. By working with a company that prioritizes customer satisfaction and provides a range of helpful resources, track and field programs can ensure a smooth and successful experience from start to finish.

Customer Service and Support

A dedicated customer service team is invaluable when navigating the process of selecting, purchasing, and installing a discus cage. Look for a manufacturer or supplier that offers:

- Knowledgeable representatives who can answer questions and provide guidance on product selection

- Multiple channels for communication, such as phone, email, and live chat

- Prompt and professional responses to inquiries and concerns

- Technical support for installation, maintenance, and troubleshooting

In addition to reactive customer service, some companies also provide proactive support through resources such as:

- Comprehensive product documentation and manuals

- Instructional videos and webinars

- FAQs and troubleshooting guides

- Regular email newsletters with tips, updates, and special offers

By partnering with a company that prioritizes customer support, track and field programs can ensure a positive and productive experience throughout the lifespan of their discus cage.

Special Offers and Pricing

When budgeting for a discus cage, it is important to consider not only the upfront cost of the equipment but also the long-term value and potential savings offered by different manufacturers and suppliers. Some companies provide special offers and pricing options that can help track and field programs maximize their investment, such as:

- Competitive pricing and price matching guarantees

- Bulk discounts for multiple cages or combined orders with other equipment

- Seasonal sales and promotions

- Financing options and payment plans

- Extended warranties and maintenance contracts

By taking advantage of these special offers and pricing options, track and field programs can stretch their budgets further and ensure they are getting the best value for their money.

E-commerce Features

In today’s digital age, a user-friendly e-commerce platform is essential for streamlining the purchasing process and providing a convenient experience for customers. Look for a manufacturer or supplier that offers a range of e-commerce features, such as:

- Secure online ordering and payment processing

- Real-time inventory tracking and order status updates

- Detailed product descriptions, specifications, and images

- Customer reviews and ratings

- Wishlist and comparison tools for easy product selection

- Quick order forms and reordering options for repeat customers

- Integration with social media platforms for easy sharing and promotion

By partnering with a company that offers a robust and user-friendly e-commerce platform, track and field programs can enjoy a more efficient and convenient purchasing experience, saving time and resources in the process.

Product Documentation and Installation

Comprehensive product documentation and clear installation instructions are essential for ensuring the safe and proper setup of a discus cage. Manufacturers and suppliers should provide detailed resources that guide customers through every step of the process, from initial planning and site preparation to final assembly and testing.

Product Documentation

A complete set of product documentation should include:

- Detailed specifications and dimensions for the discus cage and its components

- Materials lists and hardware inventories

- Assembly instructions and diagrams

- Safety guidelines and warning labels

- Maintenance and care instructions

- Warranty information and return policies

In addition to written documentation, some manufacturers also provide digital resources such as:

- CAD drawings and 3D models for precise planning and visualization

- Interactive online manuals with search and bookmark features

- Downloadable PDFs and eBooks for offline access

- Instructional videos and animations

By providing comprehensive and user-friendly product documentation, manufacturers can help customers feel more confident and prepared throughout the installation process.

Installation Instructions

Clear and concise installation instructions are critical for ensuring the safe and proper setup of a discus cage. Manufacturers should provide step-by-step guidance that covers all aspects of the installation process, including:

- Site preparation and foundation requirements

- Assembly sequence and hardware usage

- Proper alignment and spacing of components

- Netting installation and tensioning

- Final inspection and testing procedures

To make the installation process as easy and efficient as possible, manufacturers should also consider providing:

- Pre-labeled components and hardware kits

- Color-coded diagrams and visual aids

- Checklists and troubleshooting guides

- Phone or online support for installation assistance

By providing clear and comprehensive installation instructions, manufacturers can help customers avoid common mistakes and ensure a safe and successful setup of their discus cage.

In summary, a well-designed and properly installed discus cage is essential for ensuring the safety and performance of track and field athletes. By partnering with a reputable manufacturer that provides comprehensive product documentation, user-friendly installation instructions, and dedicated customer support, track and field programs can maximize the value of their investment and provide a safe and enjoyable experience for their athletes and spectators alike.